Springs and Spring Tempered Parts

At Avocet Sales & Marketing, we are equipped to provide you with the best resources in Northern California and Northwestern Nevada for any of your industrial spring needs. Through years of industry experience, we have developed the knowledge and skills to find the optimal spring solution for your project. Through our principal, Scandic, you have access to Northern California’s largest spring and spring material stamping facility.

BeCu Contact

Avocet Sales & Marketing chose Scandic to be their primary source for industrial springs due to the company’s strong engineering department and their comprehensive in-house tooling capabilities. Scandic has been providing springs and components in a number of styles and materials since 1969. Springs and spring prototypes can be manufactured using Scandic’s stamping, fourslide, or coiling technologies. Whether you have a specified design for a custom spring, or are searching for the best spring solution to an existing problem, we can help!

Capabilities for Custom Springs

Prototyping

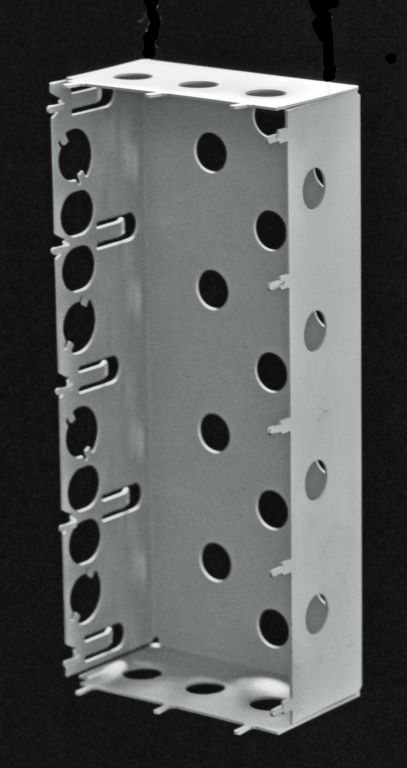

Small Board Mounted EMI Shield

Small scale production of spring concepts. Designs can be developed in a precision waterjet prototyping center using CAD files. Prototyping can save you money by providing an opportunity to test a design and a variety of materials without the costs of hard tooling or large run manufacturing.

Stamping

Straight-sided presses up to 150 tons are used for stamping a variety of thin-gage spring materials.

Fourslide

Fourslide presses are optimal for producing intricate springs, stampings, and wireforms. Fourslide presses allow for optimal material use and economies of scale.

Coiling

Coiling machines and CNC wireforming machines that provide low-cost tooling and convenient modification options.